MIL-DTL-45210B(MR)

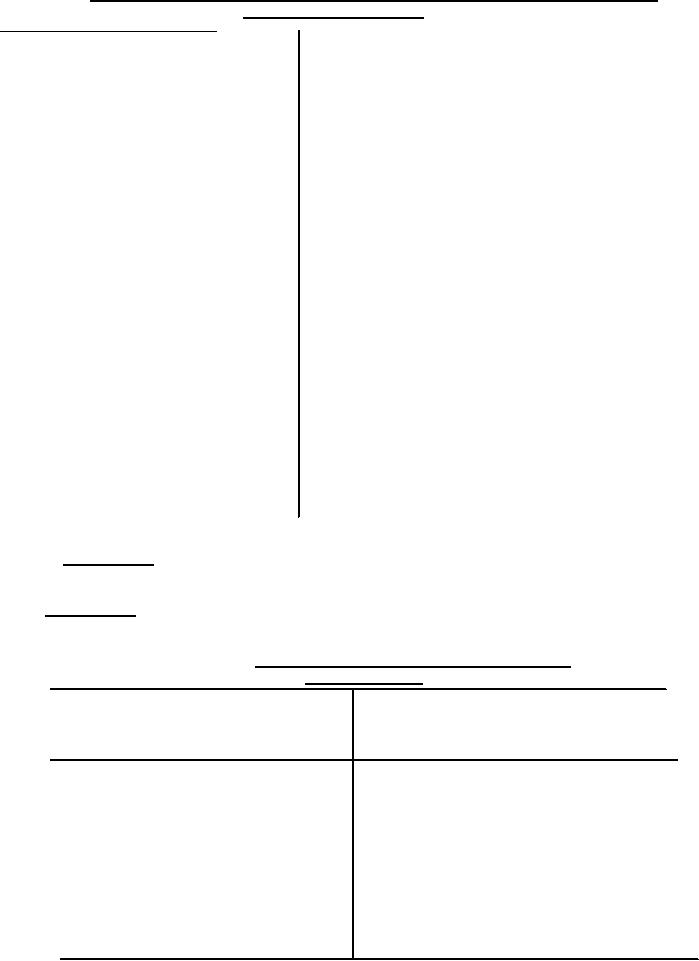

TABLE I.

Factors in the recorded welding procedure and changes requiring

quality control test.

______________________________________________________________________

Factors to be included

Procedural changes requiring

in recorded welding

revised procedures and test

procedure

_______________________________________________________________________________

1.

Metal alloy composition

When a change in alloy or alloy

composition outside the aluminum

producer's declared chemical range is

made to either of the metals that are

to be joined.

2.

Thickness range of metal

When the thickness range is changed.

3.

Weld time range

When weld cycle range is changed.

4.

Metal cleaning

When method of cleaning is changed from

the recorded methods in the welding

procedure.

5.

Welding Current

When current setting changes outside the

declared range are made.

6.

Type of current

When a change in type or polarity is

made.

7.

Electrode force range

When changes outside the declared range

are made.

________________________________________________________________________________

3.5.2 Weld timer. The weld timer for single impulse welding shall be used to

control the following timing functions: squeeze time, weld time, and hold time.

3.6 Shear load. For information (design) purposes, typical minimum ultimate

shear load per spot weld shall be as shown in table II.

TABLE II.

Typical minimum ultimate shear load

per spot weld

Typical minimum ultimate

Thickness (inch)

shear load (pound-force) per spot

thinner part *

weld (for design purposes)

0.10

50

0.020

135

0.032

235

0.040

310

0.050

430

0.063

610

0.080

855

0.090

1000

0.100

1170

0.112

1340

0.125

1625

* For intermediate thickness, direct interpolation may be used.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business