MIL-DTL-45210B(MR)

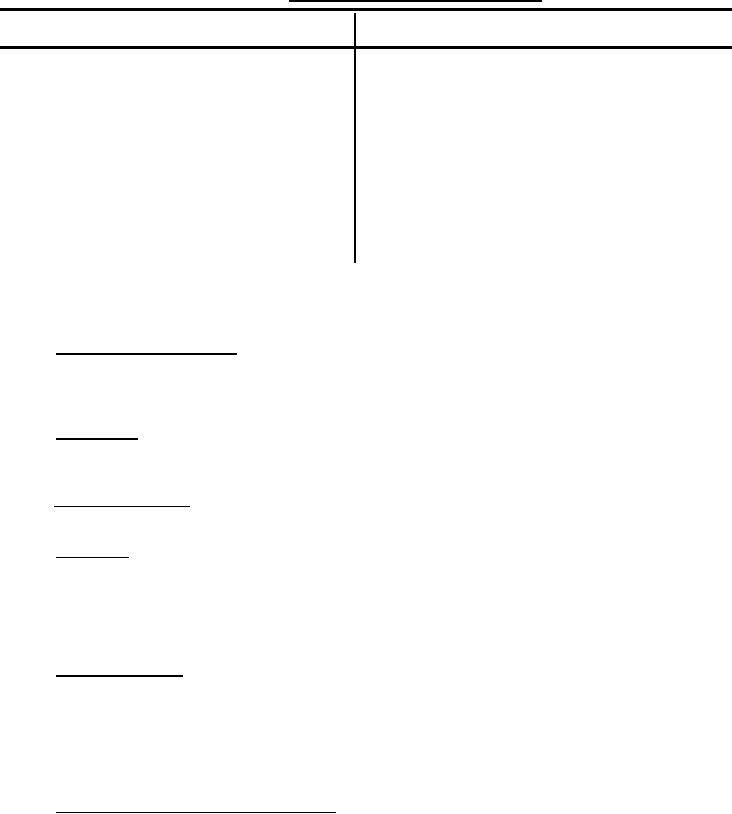

TABLE III.

Button diameter requirements.

Thickness of

Minimum bottom

thinner part, inch*

diameter, inch*

0.010

0.08

0.020

0.11

0.032

0.14

0.040

0.16

0.050

0.18

0.063

0.20

0.080

0.23

0.090

0.24

0.100

0.26

0.112

0.27

0.125

0.28

_______________________________________________________________________________

* For intermediate thickness, direct interpolation may be used.

4.6

Reporting of results. The manufacturer shall record the results of this

certification and shall submit copies of the results together with the recorded

welding procedure through the contractor and contracting officer for review by

the procuring activity.

4.7

Rejection. Failure of the welded assembly or specimens to meet the

requirements for visual examination (see 4.3) or the peel test (see 4.5) shall

result in the rejection of the recorded welding procedure.

4.8

Quality control. The contractor shall establish or have the manufacturer

establish and use a systematic quality control procedure.

4.9

Sampling. Periodically during a production run, a welded assembly or

specimen shall be tested as outlined in paragraphs 4.3, 4.4, and 4.5. The

frequency of this testing shall be specified by the contracting officer after

reviewing the production rates and types of assemblies. The contractor or the

manufacturer, or both, shall keep a record of these tests indicating date, time,

machine identification, machine settings, and results.

4.10 Rejected Welds. If unsatisfactory welds are found during a production

quality control inspection, the production run shall be stopped and necessary

corrections made to the equipment or welding procedure. After correction, a

weldment or comparable specimen shall be welded and shall conform to the

inspection requirements in 4.3, 4.4, and 4.5 before resuming production. The

series of weldments in the period subsequent to the last acceptance quality

control inspection shall be rejected or may be rewelded in accordance with 4.11.

4.11 Rewelding of rejected weldments. A weldment from each rejected series may

be rewelded in accordance with the corrected procedure. The repaired weldment

shall be tested for compliance with 4.3, 4.4, and 4.5. If the weldment passes

the inspection requirements, the remainder of the rejected series of weldments

may be rewelded in accordance with the corrected procedure. A sample shall not

be used for determining weld quality of repair welding.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business